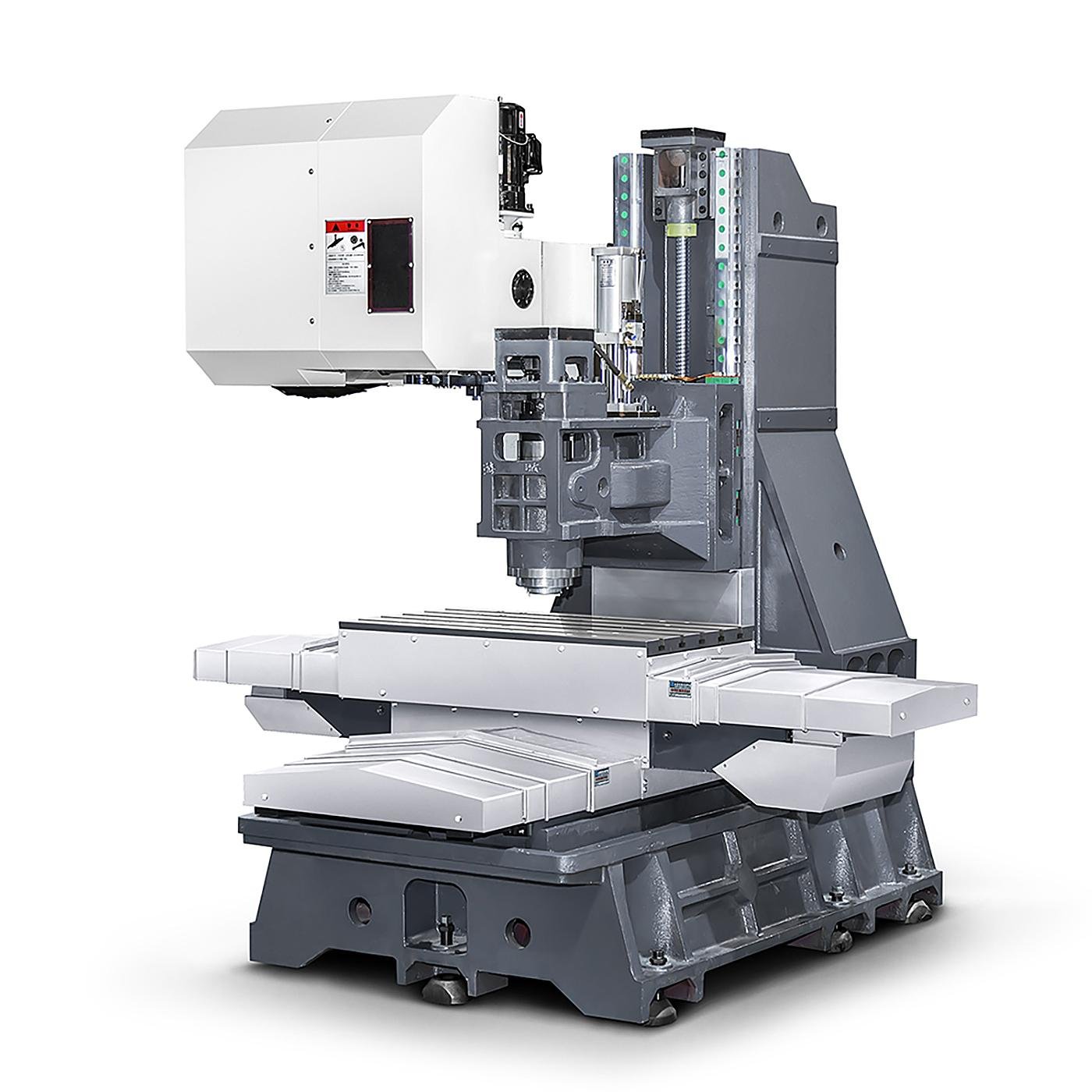

Model No.︰HM M1270/M1480/

Brand Name︰HMW

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 pc

HM M1270/M1480/M1680

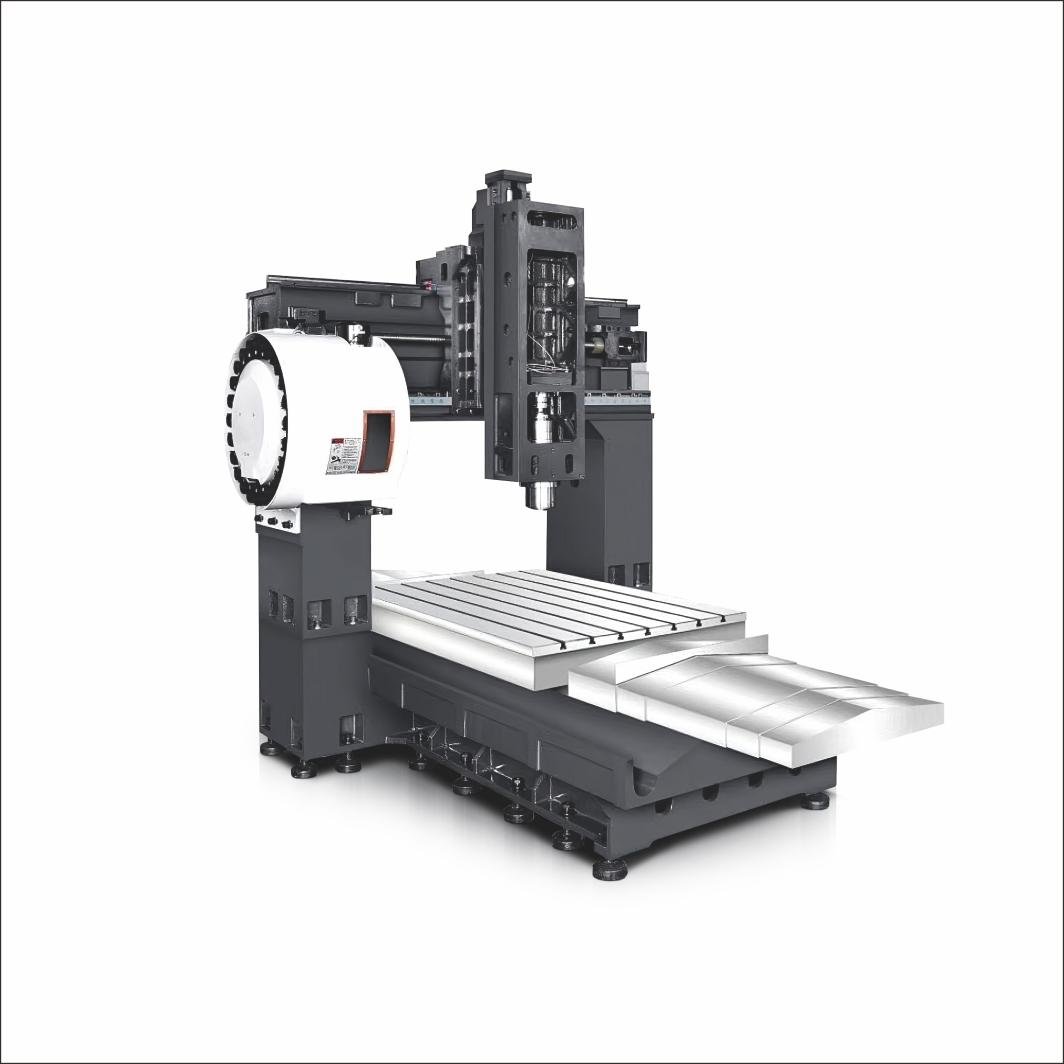

HEAVY CUTTING INTEGRATED MACHINING CENTER SERIES

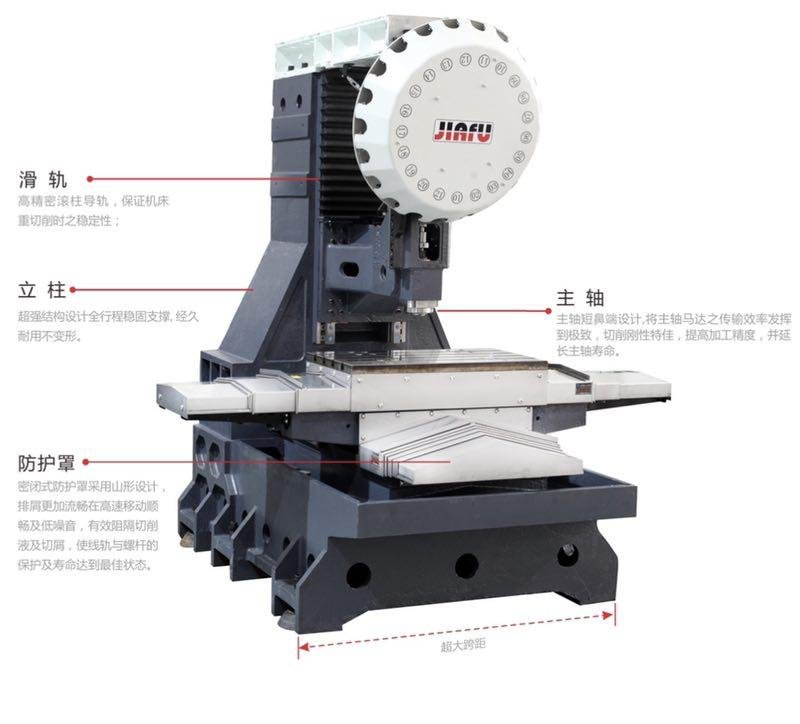

●The unique structural design, with an ultra wide base and a multi-layer cross ribbed column structure, and a reinforced spindle box design, derived from years of experience and data accumulation and rational structural analysis, greatly improves the heavy cutting ability of the entire machine while also possessing the stability of high-speed motion.

●The whole machine adopts high synthetic cast iron (HT300 material) and undergoes secondary annealing stress treatment to ensure the highest stability of the bed.

●The three axes adopt high-precision roller linear sliding rails, and the short nose end design of the large diameter direct high-speed spindle effectively improves the cutting rigidity of the spindle and reduces tool wear

THE BEST TOOL FOR PRECISION MOLDS, MOLD BLANKS, AND PARTS PROCESSING!

The unique high rigidity structural design of this series of products increases the cutting capacity by 30-50% compared to traditional equivalent models, and has advantages in precision and smoothness in precision parts and mold processing.

Widely used in product processing in various fields such as molds, molds, hardware, automotive parts, aerospace, medical equipment, etc. with complex shapes and high precision requirements.

ADVANCED DESIGN CONCEPT AND HIGH RIGIDITY STRUCTURE, ACHIEVING HIGH SPEED, PRECISION, AND STABILITY

HM M1270/M1480/M1680

MULTIPLE CONFIGURATION OPTIONS FOR YOU TO CHOOSE FROM

Precision parts and precision mold processing industries are available for selection

BT40 medium 150 direct 12000/15000rpm

Spindle, achieving high-speed and high-precision machining

Top "high-rigidity structure design" high-speed stability,extraordinary efficiency

|

item |

unit |

HMM1270 |

HMM1480 |

HMM1680 |

||

|

XYIZ axis stroke |

mm |

1200/700/700 |

1400/800/700 |

1600/800/700 |

||

|

Distance from spindle end to workbench |

mm |

100-800 |

100-800 |

100-800 |

||

|

Distance from spindle center to column guide rail surface |

mm |

780 |

880 |

880 |

||

|

Workbench size (length x width) |

mm |

1400x700 |

1600x800 |

1800x800 |

||

|

T-groove (number size spacing) |

mm |

5-18-125 |

5-18-125 |

5-18-125 |

||

|

Permissible load |

kg |

1200 |

1500 |

1800 |

||

|

Spindle cone hole - outer diameter |

No. |

BT50-Φ190 |

BT50-Φ190 |

BT50-Φ190 |

||

|

Maximum spindle speed |

r/min |

6000 |

6000 |

6000 |

||

|

Maximum power of spindle motor |

kw |

18.5 |

18.5 |

18.5 |

||

|

XYZ axis fast movement speed |

m/min |

Mitsubishi 30/30/30; Fanuc 20/20/20 |

||||

|

Maximum chip speed |

mm/min |

10000 |

10000 |

10000 |

||

|

Tool magazine (option) |

|

Disk tool magazine |

Disk tool magazine |

Disk tool magazine |

||

|

Number of tools |

T |

24 |

24 |

24 |

||

|

positioning accuracy |

mm |

±0.005/300 |

±0.005/300 |

±0.005/300 |

||

|

Repetitive positioning accuracy |

mm |

±0.003 |

±0.003 |

±0.003 |

||

|

Machine weight |

kg |

11500 |

13500 |

14500 |

||

|

Overall dimensions (length/width/height) (including chip conveyor) |

mm |

4500/2900/3200 |

4800/2950/3200 |

5300/2950/3200 |

||

|

|

Mitsubishi M80/FANUC OI-MF PLUS/Siemens 828D |

|||||