INDUSTRIAL DUST COLLECTOR FILTER AND OIL &FLUID PURIFIER CATALOG

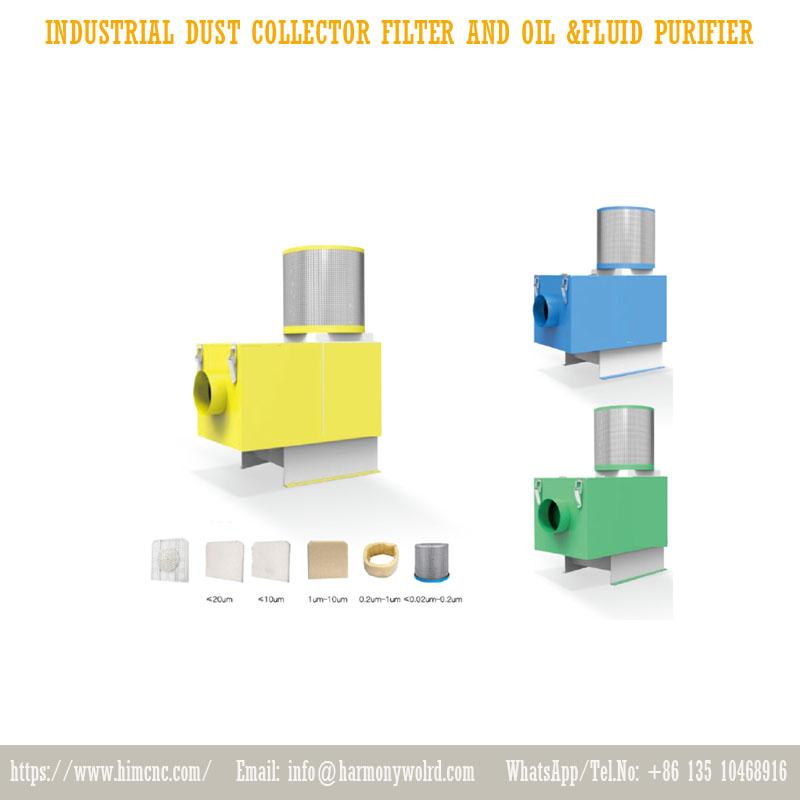

As suggested by their name, industrial and commercial dust collectors collect and remove dust and other similar particulates from the air. They are available in a variety of designs and configurations to suit different dust collection applications. We offer the following types of dust collectors and related equipment:

APPLICATIONS

Weld smoke and fumes are a leading source of air contamination in a metal fabrication facility. Some welding applications such as galvanized metal or stainless are very harmful and must be captured. Capturing smoke and fumes from welding applications can be a challenge. Make the welding fume removal process simple with a high-quality welding fume extractor.

HMWTECH Dust Collectors’ welding fume collectors use ultra-high efficiency Nano-Elite filter media that is the ideal choice for filtering the air for welding applications. Many customers return the filtered air to the workspace to conserve heat in colder weather. Other customers exhaust air outside for ventilation. Our dust collector team can help you design the welding dust collector that's perfect for any welding process you have.

WELDING FUME EXTRACTOR FOR SMOKE VENTILATION

The downward airflow technology of our welding fume extractors maximizes airflow in the collector to assist dust separation. With capabilities up to 100,000 cubic feet per minute (CFM) and more, we offer systems to cover your needs. The Nano-Elite media features a MERV 15 efficiency rating for effective collection of extremely fine dust, smoke and fume. In fact, when using Nano-Elite filters, 99.9% of particulate is captured from the air.

Does your company have a welding or cutting application that desperately needs a welding dust collector? Contact us today. We would love to show you why we have established a reputation as having the highest-value dust collectors in the industry.

Laser and plasma cutting creates a major source of fume, smoke, dust and various oxides. Therefore, it’s important to have a laser fume extractor on site for the safety of personnel and proper operation of expensive equipment. Laser cutting utilizes a focused beam of light and is recommended for applications where parts require tighter tolerances. Plasma cutting, which uses a mixture of gases to cut, is a popular process for cutting stainless steel and is widely used in the manufacturing industry.

Many laser cutting systems include integrated duct ports to connect with dust collection. The critical specifications of the laser dust collector include air-to-cloth ratio and total draw required.

A laser and plasma dust collector from HMWTECH Dust Collectors coupled with ultra-high efficiency Nano-Elite cartridge filters provides the ultimate solution. Venturi-assisted pulse clean system, premium Goyen solenoids and diaphragm valves, and the downward airflow pattern in the dust collector make the system run with maximum filter life, efficiency and effectiveness. Whether you are looking for better value by selecting an HMWTECH Dust collector for your new laser and plasma cutting process or improving your existing operation, we can recommend the appropriate solution.

LASER CUTTING SERVICES

Our team is proud to offer a laser fume extractor designed specifically for your laser cutting systems. If you’re in the laser cutting industry, our LaserPack 4 and LaserPack 6 provide a unique, heavy-duty, and effective solution for removing dust from your facility.

Both laser dust collectors feature an integrated motor/blower that is surrounded with noise attenuation material for quiet operation. Furthermore, our LaserPack dust collectors feature:

Controls that are mounted on the side of the collector and prewired for easy, on-site hookup

An optional remote start to start the LaserPack from the main laser system controls

A dust drawer base that makes for easy handling and disposal of the collected dust

The quality, ability and value of our laser fume extractors lead the laser cutting industry and are what our reputation is built on. From small to large jobs, you can rely on us to fulfill your dust collection system needs. If you’re looking for a cost-effective and efficient dust removal solution for your metal laser cutting services, look no further than HMWTECH Dust Collectors. Contact us today.

Whether you are using steel shot, grit, aluminum oxide, crushed glass, garnet, coal slag, or numerous other blast media your process makes dust. Dust in the air is harmful to your employees and slows down efficiencies.

HMWTECH Dust Collectors have been installed for many abrasive blasting operations, including both wheel blast and air blast rooms. Abrasion-resistant plenums and ultra-high efficiency Nano-Elite filter media work to increase the life of your dust collector filter. Our experts can help size new A.C.T. systems to best fit your application based on a few parameters that will increase productivity and reduce maintenance for your abrasive blasting application.

ABRASIVE BLASTING DUST COLLECTION

At HMWTECH Dust Collectors, we understand you need the right abrasive blasting dust collection system in place to handle your filtration and meet your current application and long-term needs. We’ve got the experience and history to meet the demands of your abrasive blasting operations. We design, engineer and manufacture new industrial dust collectors to help you blast correctly, efficiently, on time and below budget. Ensuring the safety of you and your employees is critical. Our Nano-Elite filters remove 99.9% of the particulate from the air stream. The cleaned air is then directed to the location of your choice, either returned to the facility or exhausted to the environment.

Metalworking equipment tends to generate a lot of dust that needs to be removed from the air. That includes the fine dust that is produced during the grinding and deburring of metals and non-ferrous metals.

When metal particles from grinding and other metalworking applications become airborne, metal dust becomes a hazard.

While grinding dust can’t be completely avoided, it can be contained and controlled. Even with state-of-the-art equipment, grinding dust has to be dealt with so that you can:

Keep your plant running efficiently with few or no interruptions

Retain team members and ensure they’re productive and happy

Maintain a safe and clean work environment

Reduce equipment maintenance costs

Having a proper industrial grinding dust collector in place will help keep your employees safe and the company in compliance with regulations and standards. By providing suitable grinder dust collectors, employees are happy and employee turnover is often reduced. This often translates to increases in production and company growth.

DISCOVER THE BENEFITS OF A DUST COLLECTOR FOR GRINDING METALS

Not sure if you need a dust collection system? If you can see, smell or taste dust in the work area, there is a need to “air out” the work area, the HVAC filters are continually clogged with dust or pieces of equipment in the facility are covered with a thick layer of dust, then you likely need an industrial grinding dust collector.

Fortunately, HMWTECH Dust Collectors offers solutions for your grinding dust collection needs. We promote hassle-free, cost-effective plant operations, and our experienced engineers work with you to select the correct size metal grinder dust collector and configuration to best capture dust, fume or smoke from your metalworking process.

Every industrial grinding dust collector we manufacture comes standard with high-efficiency Nano-Elite cartridge filters that feature a Minimum Efficiency Reporting Value (MERV) 15 rating for effective collection of extremely fine dust — capturing 99.99% of particulate from the air. Designed with quality, value and simplified maintenance in mind, quick-lock, easy-access filter doors and downward flow technology are exclusive features that allow for easy access, fast filter replacements and reduced downtime.

Powder coating is one of the fastest-growing finishing technologies in North America and an important part of many manufacturing processes, giving businesses, consumers and industries one of the most economical, longer-lasting and most durable quality finishes available on virtually any type of metal.

At the same time, however, the airborne particulate left from the powder coating process is often great in volume and creates a need for an efficient powder coating dust collector to limit any hazardous work environments. Powder can present a significant risk of combustion.

An effective powder coating dust collector can give your facility what it needs to meet local codes on requirements and ensure employee safety.

IMPROVE YOUR OPERATIONS WITH ONE OR MORE DUST COLLECTORS FOR POWDER COATING

HMWTECH Dust Collectors understands you need the right powder coating dust collectors in place to handle your filtration and meet your current application and long-term needs. We’ve got the experience and history to meet the demands of your powder coating operations.

We design, engineer and manufacture new powder coat dust collectors that use ultra-high efficiency Nano-Elite filters, which remove 99.9% of the particulate from the air stream. Our systems have more filter area than the competition, are safe and easy to use overall, require minimal maintenance and are backed by a great support team that responds quickly. You’ll be able to see the difference in performance with these systems installed in your facility.

Thermal Spray/Metallizing is a demanding application for dust collection and the HMWTECH Dust Collector is the solution. The ultra-high efficiency Nano-Elite filters capture smoke, fume, and dust, delivering air which you can return to your work environment. Our experienced engineers will work with you to select the correct size and configuration to best fulfill your thermal spray coating process requirements. Some spray metalizing options, such as explosion protection and spark detection, may be good to consider. Let our experience work for you, and we’ll remove the hassle as well as the smoke from your thermal spray operation.

DUST COLLECTORS FOR YOUR THERMAL SPRAY OPERATION

Need something to gather the fine dust particles generated during the thermal spray coating process? Consider an HMWTECH Dust Collector. Our equipment has been used in many thermal spray operations worldwide in order to collect dust particles that contain an array of metals with potential health risks. Thermal spray coating processes, including spray metallizing, produce a range of contaminants that threaten worker health and safety if not properly taken care of. Having a proper dust collection system in place can help you keep your employees safe and the company in compliance with regulations.

At HMWTECH Dust Collectors, we offer a wide range of dust collection equipment. Our sales experts have the knowledge and skills to help you reduce the dust problem at your facility the quickest and most efficient way. We offer systems that are custom designed and built, and we’ll help you find the system that works for you. Each of our dust collectors is equipped with a venturi-assisted reverse-pulse filter cleaning system and a digital, solid state pulse control panel.

Metalworking processes, including metal grinding, cutting and welding, produce a wide range of contaminants that need to be removed from the air. Having a proper industrial dust collection system in place will help you keep your employees safe and the company in compliance with regulations.

At HMWTECH Dust Collectors, every metalworking dust collector we manufacture comes standard with high-efficiency Nano-Elite cartridge filters that feature a MERV 15 efficiency rating for effective collection of extremely fine dust, smoke and fume — capturing 99.9% of particulate from the air.

Our industrial metalworking dust collectors are designed with quality, value and simplified maintenance in mind, no matter the application. Quick-lock, easy-access filter doors and downward flow technology are exclusive features that allow for easy and fast filter replacements and greatly reduce downtime.

METALWORKING DUST COLLECTORS YOU CAN RELY ON

Our industrial dust collection systems have been used in many metalworking operations around the globe in order to collect fume and smoke particles that contain an array of metals, especially grinding dust. Even though grinding dust can’t be completely avoided, it can be contained and controlled.

METAL GRINDING DUST COLLECTORS

Not sure if you need a grinding dust collector? If you can see smog or a cloud of dust in the work area, there is a need to “air out” the work area, the HVAC air vents and filters are continually clogged with dust or pieces of equipment in the facility or work area are covered with a thick layer of dust, then you likely need a metal grinding dust collector.

HMWTECH Dust Collectors promotes hassle-free, cost-effective plant operations, and our experienced engineers work with you to select the correct size metal grinding dust collector and configuration to best capture dust, fume or smoke from your metalworking process.

BENEFITS OF OUR METALWORKING DUST COLLECTORS

They hold more dust than the competition, meaning less maintenance and cleaner air.

They’re safer and easier to use overall.

From RFQ to installation, they can be up and running in no time.

They’re backed by a team of experts.

HIGH-QUALITY METALWORKING DUST COLLECTORS

HMWTECH Dust Collectors has the knowledge, skill and experience to help you quickly and efficiently eliminate dust at your facility. Our wide range of standard industrial dust collector sizes accommodate most needs, and some sizes are in stock for quick-ship.

Custom industrial dust collection systems can be designed and built, and we’ll make sure you find the system that works for you. Each of our dust collectors are equipped with a venturi-assisted reverse-pulse filter cleaning system and a digital, solid-state pulse control panel.

Thousands of industrial environments create airborne particles, ranging from sub-micron size smoke to large chunks of plastic, paper, or wood. Some dust is hazardous and presents a safety issue. Other dust reduces visibility and needs to be removed. Many processes pulverize aggregate and the dust is the finished product to capture, package and sell. Operations creating fume and smoke use industrial dust collection systems to clear the air of haze.

HMWTECH Dust Collectors have been installed in hundreds of processes, capturing dust from industrial environments in the most efficient, economical, and safe way. Ultra-high Nano-Elite filters, premium Goyen pulse-clean systems, quick lock filter doors, and industry-best pricing make the HMWTECH Dust Collectors the leader in industrial air filtration.

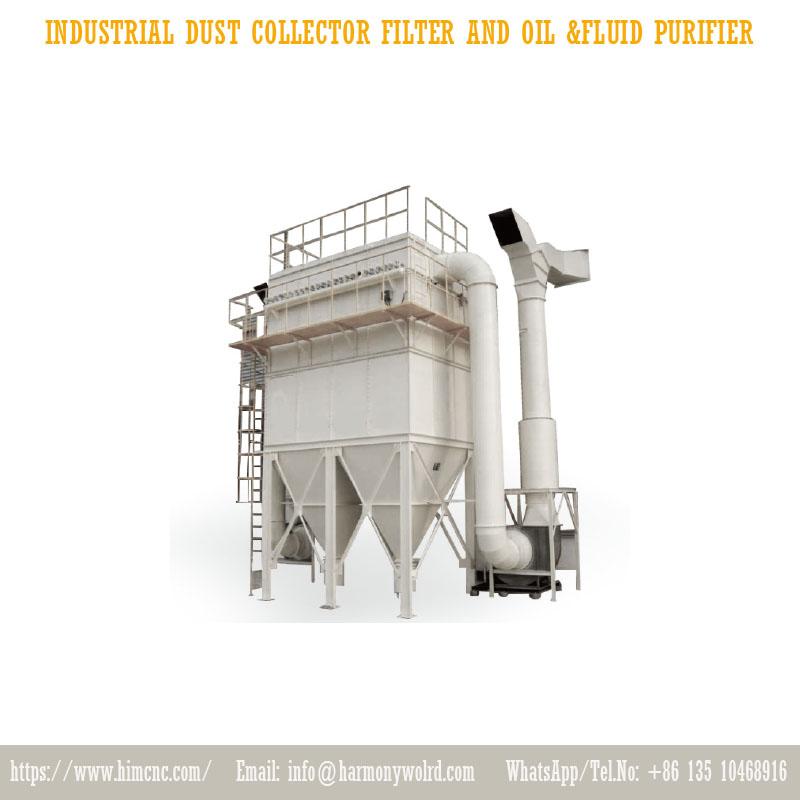

INDUSTRIAL DUST COLLECTOR

In need of an industrial dust collection system? At HMWTECH Dust Collectors, we have the experience and history to handle the most demanding applications at your facility. Each industrial air filtration system is quality-built right here in America to stand up to your rugged manufacturing environment. Our industrial dust collectors come in many makes and models, including:

Cartridge Dust Collectors

Baghouse Dust Collectors

LaserPack

Whatever industrial dust collector you need, our expert staff will make sure it is designed and built to fit your environment. We have manufactured and installed hundreds of dust collectors, and every serial number is a statement of quality. With us, you can expect lifting lugs engineered to the correct lifting angle, formed doors for maximum rigidity, and deep one-piece gaskets to maintain a secure seal. Angle iron support structure and base plates are pre punched for easy installation, and a premium blast, prime and paint process ensures your industrial dust collection system will remain in excellent cosmetic condition for many years.

Numerous pharmaceutical operations create airborne particles that require collection. Fluid bed drying, tablet making, pill coating and drying processes are just a few.

Pharmaceutical Dust Collectors are perfect for these applications, using ultra-high efficiency Nano-Elite filter media for sub-micron particle capture. Safety HEPA after filters are available when required. Our engineers help design systems built from stainless steel that are resistant to corrosion and compliant with explosion protection. Some processes require special handling of collected dust for reuse, others are hazardous and changing cartridges requires special equipment. HMWTECH Dust Collectors have been installed in many pharmaceutical applications. Let us help to find the ultimate in safety and efficiency for you.

RELIABLE PHARMACEUTICAL DUST COLLECTORS

If you’re in need of a pharmaceutical air filtration system, turn to HMWTECH Dust Collectors. The customer service, price, and quality associated with our dust collectors make us the go-to solution for removing airborne particles. Our stainless steel dust collectors are especially crucial in pharmaceutical operations. In fact, we currently have several stainless steel dust collectors in the field and have mastered the balance of making these systems the highest quality at a reasonable price.

We have successfully installed numerous systems worldwide, and with our technical expertise and factory support, you can feel confident about having a pharmaceutical dust collection system installed for your operation. At HMWTECH Dust Collectors, we provide ready-to-ship parts and filters, with systems tailored to your specific needs. Our professional design and engineering experts can offer the best support for your inquiries. Perfection is our goal, and we aim to provide complete satisfaction and excellent value to all our customers, including you! To speak with a team member about what system is right for your pharmaceutical operation, call 763-557-7162.

READ PHARMACEUTICAL CASE STUDIES

PHARMACEUTICAL: A LARGE COMPANY NEEDED 4 UNITS FOR USE ON A FLUIDIZED TABLET COATING

Robotic welding is a demanding application for dust collection and the HMWTECH Dust Collector is the solution. Robotic weld cells are no longer for the elite, exclusive manufacturing facilities, they are becoming more and more common taking over the tedious, repetitive tasks.

Robotic welding requires additional dust collection for the cell due to the large volume of dense smoke it creates. A robotic welding facility needs an efficient air quality system in place to meet safety regulations.

The LaserPack series and the WeldPack series from HMWTECH Dust Collectors both feature a small footprint, are easy to install, and simple to integrate with your robotic welding system.

DUST COLLECTORS FOR YOUR ROBOTIC WELD CELL

Robotic weld cell are more common in manufacturing facilities as they can perform tasks faster and with fewer errors than humans. To keep the robots running at maximum efficiency they need to operate in a clean environment. Dust and fumes will affect the robot and potentially lead to expensive optical and mechanical failure. A properly designed fume collection system will allow the robots to perform at peak efficiency with minimal down time and will also keep workers from being exposed to potentially harmful weld fume. HMWTECH Dust Collectors introduced the WeldPack unit specifically to tackle robotic welding.

Considering the advantages of robotic welding, it is likely to become more common throughout various industries. The quality of robotic welding is high, consistent and also requires dust collection - that is where we can assist.

At HMWTECH Dust Collectors, we offer a wide range of dust collection equipment such as the WeldPack and our Cartridge Collectors. Our sales experts have the knowledge and skills to help you reduce the dust problem at your facility in a quick and efficient way.

Dust is an annoying byproduct of sanding, whether from wood, metal, plastics, etc. This fine, powdery dust can also have negative effects on your health and work environment, as well as your equipment.

Allowing dust to accumulate on your equipment can cause defects, as you could be sanding the dust particles into your surface, rather than sanding the work surface itself. If dust is left on the surface when applying stains or other similar products, these defects will be visible in the finish. As a result, you’ll end up spending more time sanding your pieces.

This accumulation of dust can pose a potentially hazardous condition — combustible dust — generated from products such as wood, metals and plastics.

Prevent combustible dust in your facility with a fine particle dust collector from HMWTECH Dust Collectors.

ADVANTAGES OF OUR DUST COLLECTORS FOR FINE PARTICULATES

Every sanding dust collector we manufacture comes standard with high-efficiency Nano-Elite cartridge filters that feature a Minimum Efficiency Reporting Value (MERV) 15 rating for effective collection of extremely fine dust — capturing 99.99% of particulate from the air. Additionally, our dust collectors for sanding:

Designed and built with the user in mind, meaning less maintenance time and cleaner air

Are safer and easier to use overall

Can be up and running in no time, from RFQ to installation

Are backed by a team of experts

Happier employees

With a sanding dust collector on site, not only will you clear the air of combustible dust, but you’ll improve employee efficiency, increase employee retention, help ensure a safe working environment and reduce equipment maintenance costs.

Many people think of dust collection systems mainly being used for metal working and wood working applications. They do not consider the operations that take place to make the food we eat such as food processing applications. Ingredients as common as sugar, flour, and spices are made through methods that create dust and that dust is explosive!

In food processing, the fine particles from mixing and blending are released into the air as the ingredients are processed and packaged. In a recent sugar substitute application, we tested the dust and found that it was explosive.

Cartridge Dust Collectors well as the TLM Baghouse Dust Collectors are designed for food processing application like this. Many of our customers have installed our systems to capture dust from grain, flour and sugar substitute applications. Chemical explosion suppression systems are available to help detect a pressure wave of an explosion and inject sodium bicarbonate that takes the flame out of the explosion.

The team at HMWTECH Dust Collectors can help you determine whether a baghouse or cartridge unit is best for your application. There are many factors that can make one option more efficient for food processing applications than others. Click here to learn about the differences of a baghouse verse cartridge collector.

At HMWTECH Dust Collectors, we understand you need the right food processing dust collection system in place to handle air filtration and meet the current application and long-term needs. We have the experience and history to meet the requirements of your food processing applications operations. We design, engineer and manufacture new industrial dust collectors to help you process and make ingredients efficiently, on time and below budget. Ensuring the safety of you and your employees is critical. Our Nano-Elite filters remove 99.9% of the particulate from the air stream. The cleaned air is then directed to the location of your choice, either returned to the facility or exhausted to the environment.

Most activities in today’s world are influenced or depend on plastic products. From cars to communication methods to entertainment to the office, plastics are everywhere. All of these plastic products are made from polymers and a complex blend of materials known as additives.

Processes such as extrusion, blow molding, injection molding and 3D printing are all specific applications where plastics are created and formed. In these processes of combining materials, a variety of forms of dust particulate are released. Whether this particulate is fine dust from sanding or deburring plastics or if it is from the crushing and shredding of recycled plastics, it is important that this material is properly collected and removed from the air. This is when you need to use an industrial dust collection system to gather the particulate from the air to help ensure a safe working environment.

HMWTECH Dust Collectors have been installed in hundreds of processes, capturing dust from plastic applications in the most efficient, economical, and safe way. Ultra-high Nano-Elite filters, premium Goyen pulse-clean systems, quick lock filter doors, and industry-best pricing make the HMWTECH Dust Collectors the leader in industrial air filtration.

COLLECTING PLASTIC PARTICULATE

At HMWTECH Dust Collectors, we understand you need the right dust collection system in place for your plastic application, to handle your filtration and meet your current and long-term needs. We have the experience and history to meet the demands of your plastic operations. We design, engineer and manufacture new industrial dust collectors to help you manufacture plastics correctly, efficiently, on time and below budget. Ensuring the safety of you and your employees is critical. Our Nano-Elite filters remove 99.9% of the particulate from the air stream. The cleaned air is then directed to the location of your choice, either returned to the facility or exhausted to the environment.

Looking for air pollution control for your recycling and scrap applications? If you are in the recycling industry and that process includes shredding, grinding, cutting or other dust-creating processes, we have dust collection options for you.

From car dismantling to metal cutting to electronics shredding, HMWTECH Dust Collectors has engineered solutions for dealing with the dust created. We can do the same for your process.

Capturing fume and/or smoke from an outdoor cutting operation? Some of our unique, engineered solutions include roof installations and buildings that move on rails to accommodate the specific processes and needs of our customers.

Our dust collectors have a capacity range of 1,000 CFM (cubic feet per minute) to 75,000 CFM. The downward airflow technology maximizes airflow in the collector to assist dust separation. Regardless of how small or large your capacity needs are, we manufacture an industrial dust collection system that will help provide maximum air filtration efficiency. Our dust collectors also have a compact footprint.

INDUSTRIAL DUST COLLECTING DONE RIGHT

Dust collectors help to keep the air in your surrounding environment clean and safe for everyone involved. Dust collectors are important for a lot of reasons as they:

Increase productivity

Lead to better product quality

Meet compliance regulations

Improve the morale of your employees

Whatever dust collection system you need, we will make sure it is designed and built specifically for your recycling process. With us, you can expect lifting lugs engineered to the correct lifting angle, formed doors for maximum rigidity and deep one-piece gaskets to maintain a secure seal. Our technicians and quality control teams ensure every dust collector is up to our standards before stamping our serial number on it.

YOUR SOURCE FOR A HIGH-QUALITY INDUSTRIAL DUST COLLECTION SYSTEM

At HMWTECH Dust Collectors, we have the experience, knowledge, and skill to help you quickly and efficiently eliminate dust from your outdoor cutting operations. Our array of standard industrial dust collection systems cater to most needs, and some sizes are in stock for quick-ship.

Nearly every woodworking operation requires some form of dust collection. Ranging from fine sanding dust to large molder chips, wood dust can be quickly and efficiently captured for either disposal or reuse. Using effective inlet design, bag filters, and pulse clean, AChouse Dust Collectors can handle most woodworking applications.

HMWTECH Dust Collectors have been installed in hundreds of processes, capturing dust from numerous woodworking operations. The TLM Series Baghouse has risen to an industry leader using an exclusive hinged filter access door, swing-away blowpipe design, and tool-free bag filter access system. Maintenance no longer requires confined space entry, and bags are accessed from the clean side for easy changing. Contact our woodwork dust collector experts to learn how the A.C.T. baghouse can transform your dust collection needs.

RELIABLE WOODWORKING DUST EXTRACTORS FOR YOUR APPLICATION

When it comes to maintaining a safe and healthy work environment for you and your employees, you need a reliable dust collection system in place. Our TLM Modular Baghouse dust collector is just that, designed to meet the unique requirements of each application. Not only is installation easy and straightforward with the modular design and integral lifting lugs, but operation is simple, proven and efficient. Dust-laden air is drawn from the source through a duct system and into the hopper inlet. Through air expansion and an internal deflection plate, the airstream velocity is reduced so large particles drop into the hopper below. The remaining dust particles are filtered through bag filters to ensure that only cleaned air passes into the clean air plenum, through the fan, and is either exhausted to the atmosphere or returned to your building, depending on the installation configuration.

Product overview

FILTER CARTRIDGE TYPE INDUSTRIAL DUST COLLECTOR

Product characteristics

Independent PLC control system, fully intelligent programmable control. 7-inch LCD display screen, touch and dialogue operation.

Imported filter cartridge with falling film external treatment, with a filtration accuracy of up to 0.1 micrometers.

During the process of vacuum cleaning, the dust will be attached to the dry filter element, which will affect the vacuum cleaning effect; We flush the interior of the speed core with strong air pressure within the time set by the system to prevent dust adsorption.

When the filter element reaches its service life (1 year/360 days of normal use, with a replacement calculated at 8 hours per day), the system will alarm and prompt for replacement to avoid affecting the normal use of the equipment.

Frequency conversion energy-saving function: The turbine speed can be adjusted according to the amount of dust during processing (generally, during precision machining, the dust amount is small, and the vacuum cleaner runs at full load, which is a waste of electricity). At this time, only the adjustment on the operation panel is needed.

Remote control function: The power supply can be connected to the machine tool, and the vacuum cleaner can be started, stopped, and stopped when the spindle rotates (it can also be started or stopped randomly, that is, the vacuum cleaner can be started and stopped synchronously).

Application industry and scope

Suitable for: (dry dust treatment) such as: metal polishing dust, furniture cutting polishing dust, stone cutting polishing dust, medicinal material processing dust, graphite processing powder Dust, machine tool grinding and cutting dust, lithium battery processing dust, (laser engraving machine, welding machine, automation robot matching, and other equipment that generates dry dust) And workstation usage). The filtered gas can be directly discharged indoors, and the dust recovery rate can reach over 99%.

| Model No. |

HVMD-2200 |

HVMD-3000 |

HVMD-3700 |

|

|

|

|

|

| Power supply system |

380/50 |

380/50 |

380/50 |

|

|

|

|

|

| Rated power |

2.2 |

3.0 |

3.7 |

|

|

|

|

|

| Rated current |

3.2 |

4.5 |

6 |

|

|

|

|

|

| Dust rate( >um) |

99.99 |

99.99 |

99.99 |

|

|

|

|

|

| Rated air volume |

2800 |

3600 |

4300 |

|

|

|

|

|

| Max wind speed |

28m/S |

32m/s |

36m/s |

|

|

|

|

|

| Max wind pressure |

1300-1800 |

1800-2200 |

2000-2500 |

|

|

|

|

|

| the measure of area |

8 |

22.0 |

22 |

|

|

|

|

|

| quantity |

2 |

2 |

4 |

|

|

|

|

|

| Suction diameter |

Medium 150/200mm |

200/250mm |

200/250mm |

|

|

|

|

|

| Exhaust diameter |

360/1 in the middle |

360/pc |

360/1pc |

|

|

|

|

|

| Phonetics |

72+2 |

72+2 |

73+2 |

|

|

|

|

|

| Dust box capacity |

50 |

50/60/75 |

75 |

|

|

|

|

|

| Primary color |

OEM/ODM |

OEM/ODM |

OEM/ODM |

|

|

|

|

|

| Boundary L*W * H |

850*680*1600 |

820*800*2000 |

820800*2000 |

|

|

|

|

|

| Weight (gross weight) |

220 |

280 |

280 |

Product characteristics

●Independent PLC control system, fully intelligent programmed control. 7 inch LCD screen, touch, conversational operation.

●High quality filter cartridge plus membrane coating, filtration accuracy up to 0.1 micron (nano level). This is a general vacuum cleaner, which is "beyond the reach of dust".

●During the suction process, the dust will adhere to the filter element, which will affect the dust suction effect; We flush the inside of the filter element under strong air pressure within the time set by the system

Wash to prevent dust adsorption.When the filter element reaches the service life (normal use of 1 year/360 days, replacement once is counted as 8 hours per day), the system will alarm to prompt replacement, so as not to affect the equipment

Normal use frequency conversion energy-saving function: the turbine speed can be adjusted according to the amount of dust during processing (generally the machine tool machine tool is small when the dust amount is small, and the vacuum cleaner is fully loaded Turn, it is a waste of electricity), then only need to adjust on the operation panel.

Remote control function: the power supply can be connected to the machine tool, set the vacuum cleaner to start when the spindle rotates, stop the spindle, and stop the vacuum cleaner (can also be started and stopped randomly by the bed stop, that is, the vacuum starts and stops synchronization).

Industries and scopes of application

Suitable for: (dry dust treatment) such as: hardware polishing dust, furniture cutting and polishing dust, stone cutting and polishing dust, medicinal materials processing dust, graphite processing powder dust, machine tool grinding and cutting dust, lithium battery processing dust, (laser machine, engraving machine, welding machine, automatic robot matching, and other equipment that produces dry dust and workstation use). The filtered gas can be discharged indoors, and the dust recovery rate is more than 99%.

| Model NO. |

unit |

HVDM-5500 |

HVDM-7500 |

| Power supply system |

V/HZ |

380/50 |

380/50 |

| Rated power |

KW |

5.5 |

7.5 |

| Rated current |

A |

10.6 |

13.2 |

| Dust removal rate (particle size≧μm) |

% |

99.99 |

99.99 |

| Rated air volume |

m3/h |

4800-5800 |

8000 |

| Max wind speed |

m/s |

45m/S |

49m/S |

| Max wind pressure |

PA |

1800-2400 |

1800-2400 |

| Area |

m2 |

60.0 |

72 |

| Quantity |

mm |

6 |

6 |

| Suction caliber |

mm |

250/300mm |

300/350mm |

| Exhaust caliber |

Db(A) |

360/1个 |

360/1个 |

| Noises |

L |

74±2 |

75±2 |

| Container capacity |

mm |

80/95/110 |

85 |

| Color |

KG |

OEM/ODM |

WHITE |

| dimensions L*W*H |

V/HZ |

960*920*2100 |

1200*1100*2350 |

| (Gross Weight) |

KW |

330 |

600 |

Product characteristics

No filter design combines the world's most advanced dynamic interception with swirl technology

It can effectively purify all kinds of high-temperature sparks, dust, oily and adhesive dust, fibers and various metal waste chips. In particular, metal polishing and grinding, surface grinding machines and large water mills are the most ideal dust removal and purification equipment.

No need to change consumables No filter design, there will never be clogging, and the suction power can remain unchanged all year round.

According to customer needs, the addition of spray function can be selected.

Industries and scopes of application

Suitable for: (wet, oily, dry, high-risk flammable and explosive dust treatment) such as: magnesium powder, aluminum powder, coal ash, flour, starch, and other flammable synthetic materials dust treatment. Other industry applications such as: hardware polishing dust, furniture cutting and polishing dust, stone cutting and polishing dust, medicinal materials addition

Industrial dust, machine tool grinding and cutting dust, lithium battery processing dust, etc. The filtered gas can be discharged indoors, the dust recovery rate is more than 99%, and it is not blocked, and the air volume is consistent all year round.

| Model no. |

units |

HGF-30 |

HGF-50 |

| Power supply system |

V/HZ |

380/50 |

380/50 |

| Rated power |

KW |

3.7 |

5.5 |

| Rated current |

A |

8 |

11 |

| Rated air volume |

m3/h |

2400 |

3200 |

| Max wind speed |

m/s |

21(200) |

29(200) |

| Rated wind pressure |

PA |

400 |

800 |

| Suction caliber |

mm |

Ф200 |

Ф200 |

| Exhaust caliber |

mm |

Ф(500*500)*2 |

Ф(500*500)*2 |

| noises |

Db(A) |

72±2 |

72±2 |

| Dust container capacity |

mm |

92 |

110 |

| color |

white |

OEM |

OEM |

| Overall dimensions L*W*H |

mm |

800*800*2000 |

960*1100*2200 |

| Weight |

KG |

230 |

270 |

Product characteristics

In recent years, dust explosion accidents have occurred frequently, especially in the aluminum processing industry, more and more people are aware of the huge harm caused by dust explosions, and regulatory authorities at all levels have paid more and more attention to flammable and explosive materials, and must take necessary explosion-proof precautions to protect personal and property losses. Our company has many years of dust explosion-proof design experience, and conventional products have also obtained national recognized explosion-proof product certification.

| Order no. |

units |

HFD-2200 |

HFD-3700 |

HFD-5500 |

| Power supply system |

V/HZ |

380/50 |

380/50 |

380/50 |

| Rated power |

KW |

2.2 |

3.7 |

5.5 |

| Rated current |

A |

5 |

8 |

11.6 |

| Dust removal rate (particle size≧ 1μm) |

% |

99.999 |

99.999 |

99.999 |

| Rated air volume |

m³/h |

2800 |

4000 |

5800 |

| Maximum wind speed |

m/s |

22(Ф200) |

32(Ф200) |

40(Ф250) |

| Rated wind pressure |

PA |

2100 |

2600 |

2600 |

| area |

m2 |

18 |

26 |

45 |

| quantity |

pc |

2 |

4 |

4 |

| Suction caliber |

mm |

150/200 |

200/250 |

250/300 |

| Exhaust caliber |

mm |

Ф360 |

Ф360 |

Ф360 |

| noises |

Db(A) |

72±2 |

73±2 |

74±2 |

| Dust container capacity |

L |

70 |

50/60/83 |

85 |

| color |

white |

OEM |

OEM |

OEM |

| Overall dimensions L*W*H |

mm |

850*680*1600 |

820*800*2000 |

960*920*2100 |

| Weight (Gross Weight) |

Kg |

200 |

220 |

270 |

Product characteristics

Manual dust cleaning, easy to use. No blockage, large air volume, can absorb water, oil, cutting fluid, metal waste residue, etc.

Dimensions L "W * H (mm) : 230*230*800

Weight (Gross Weight): 9KG

Product characteristics

GH series oil mist purification machine adopts centrifugal separation and high-efficiency filtration technology, after the oil mist purification machine 5-stage filtration treatment, the oil mist collection efficiency is more than 99%, can reduce the influence of dry smoke, oil mist on the machine tool circuit system, control system, reduce the maintenance cost of machine tools. Improve the working environment, achieve cleaner production, protect the physical and mental health of employees, and reduce the occurrence of occupational diseases.

Industries and scopes of application

It is suitable for oil mist and water-based mist generated during processing of cutting fluids, emulsions and synthetic coolants. CNC lathes, machine tools, external cylindrical, surface grinding Bed, CNC machining center.

Product characteristics

"Spray tower" is suitable for hardware, building materials, ceramics, electronics, chemical industry, casting, aluminum products, metallurgy, mechanical processing, non-ferrous metals and other industrial fields of waste gas dust purification, generator boiler exhaust gas treatment, acid and alkali waste gas purification, etc.

Order No. HTW-050

Product characteristics

"Cyclone tower" is suitable for waste gas dust purification treatment in various industrial fields (especially suitable for spray painting waste gas paint mist treatment, grinding and polishing dust treatment, etc.). The cyclone tower has the advantages of low resistance, energy saving, low noise and treatment, and can handle a variety of dust and exhaust gases.

ORDER NO.HWT-100

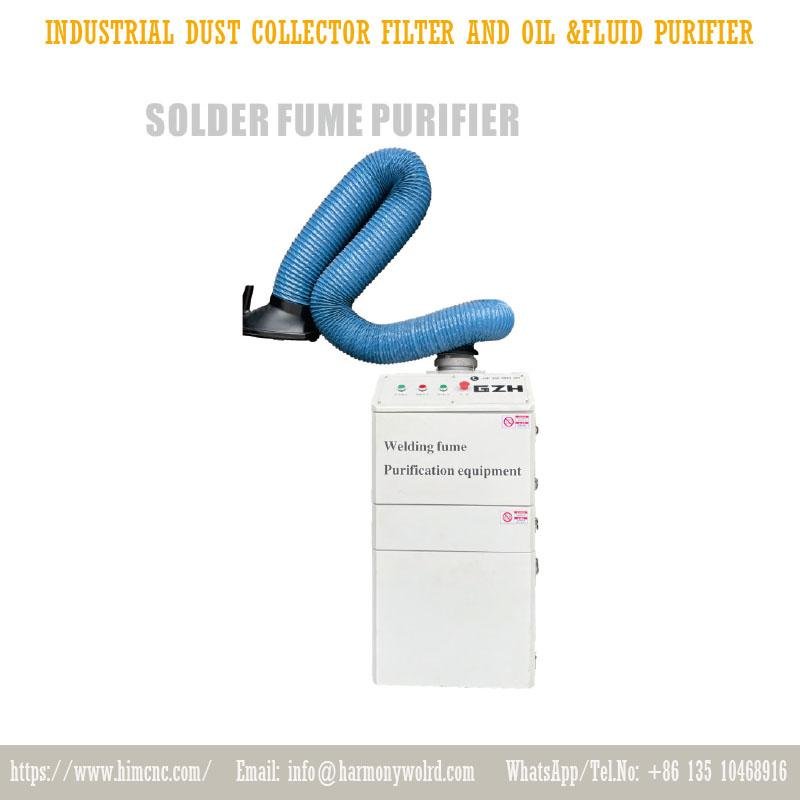

Welding fume purification equipment

Product characteristics

YCJH series solder soot purifier is a laser industry soot purifier developed by our company in combination with environmental protection emission requirements, which has the advantages of large air volume, stable and reliable, small footprint, simple structure, economy and practicality.

Parameter ORDER NO. HYCJH-1000, HYCJH-2000, HYCJH-3000

| Model No. |

unit |

HYCJH-1000 |

HYCJH-2000 |

HYCJH-3000 |

| Power supply system |

V/HZ |

380/50 |

380/50 |

380/50 |

| Rated power |

KW |

1.5 |

2.2 |

3.0 |

| Rated current |

A |

3 |

4.4 |

6 |

| Dust removal rate |

% |

99.999 |

99.999 |

99.999 |

| Rated air volume |

m³/h |

2350 |

3150 |

3850 |

| Max wind speed |

m/s |

25(Ф160) |

34(Ф160) |

45(Ф200) |

| Rated wind pressure |

PA |

500 |

700 |

900 |

| Precision |

μm |

0.3 |

0.3 |

0.3 |

| Quantity |

pc |

2 |

2 |

2 |

| Suction caliber |

mm |

Ф160 |

Ф160 |

Ф160 |

| Suction arm length |

M |

3 |

3 |

3 |

| Noises |

Db(A) |

72±2 |

72±2 |

72±2 |

| Dust truck capacity |

L |

10 |

12 |

15 |

| Color |

White |

customized |

customized |

customized |

| Dimensions L*W*H |

mm |

600*700*120 |

700*800*1200 |

750*920*1200 |

| Weight |

kg |

80 |

100 |

130 |

ELECTROSTATIG FUME PURIFIER parameters

| Double-layer model |

Handle air volume |

Form factor |

Air outlet size |

Input voltage |

power |

Purification efficiency |

Wind resistance |

| LBHB_DK_12B |

12000 |

910*655*1252 |

430 |

220 |

600 |

98% |

<150 |

| LBHB_DK_16A |

16000 |

910*845*1252 |

620 |

220 |

600 |

98% |

<150 |

| LBHB_DK_20A |

20000 |

910*1030*1252 |

805 |

220 |

1200 |

98% |

<150 |

| LBHB_DK_24A |

24000 |

1285*845*1252 |

620 |

220 |

1200 |

98% |

<150 |

| LBHB_DK_30A |

30000 |

1285*1030*1252 |

805 |

220 |

1200 |

98% |

<150 |

CENTRAL DUST COLLECTION OF HIGHPOWER DUST REMOVAL EQUIPMENT

CENTRAL DUST COLLECTION (VJGG11KW)

Provide customized equipment strive to achieve more energy-saving,

economical, more efficient and more stable central dust collection machine.

CENTRAL DUST COLLECTION OF HIGHPOWER DUST REMOVAL EQUIPMENT