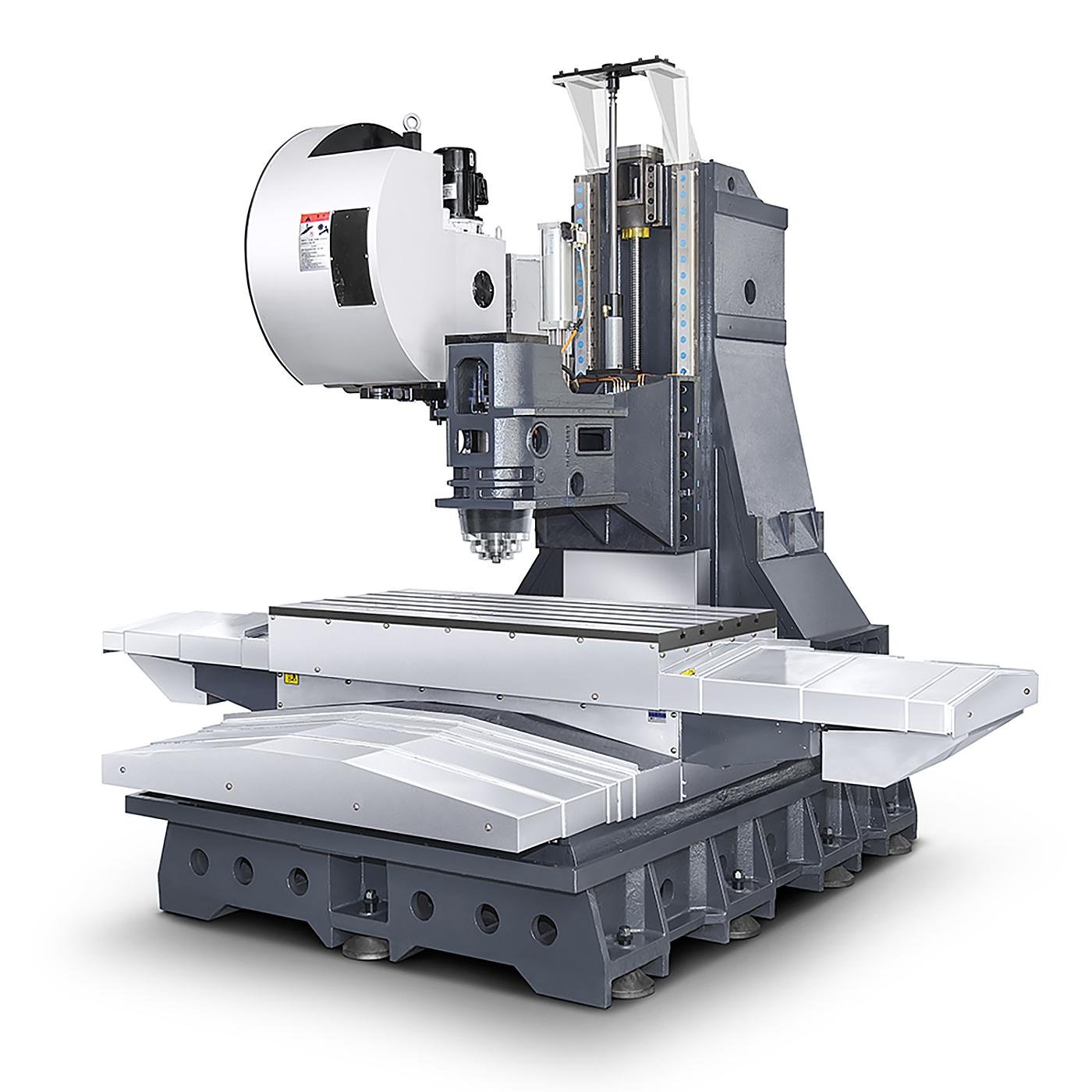

Model No.︰HM T600/T800

Brand Name︰HMW

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 pc

HIGH-SPEED DRILLING CENTER SERIES

●A small high-speed drilling iron tapping machining center with comprehensive high rigidity milling capabilities.

●The powerful BT30 taper direct drive spindle has high rigid tapping efficiency and a rotational speed of up to 20000 rpm.

●The combination of a fast moving speed of 60m/min and high acceleration shortens the idle working time of the processing cycle.

●The fully sealed integrated rice gold design, with the entire set of outer covers fixed inside the base casting, eliminates the problem of chip liquid leakage.

●The three axis adopts imported silent roller linear slide rails, which have the characteristics of high accuracy, high movement speed, and good accuracy retention.

●Through finite element analysis, ensure the optimal structural design of the machine, providing overall high accuracy and rigidity.

THE BEST TOOL FOR MASS PRODUCTION AND PROCESSING OF 3C PARTS

This series of products has a unique high rigidity structural design, greatly improving cutting ability, and has high stability, high-speed and efficient processing characteristics. It is widely used in the 3C industry, electronic shell processing, automation, aerospace, automotive small parts, medical equipment and other industries, as well as shell processing.

FAST DISPLACEMENT WITH HIGH-SPEED TOOL CHANGE MECHANISM

CAN BETTER REFLECT THE EFFICIENCY OF OBSERVATION AND PROCESSING

HM T600/T800

PERFECT COMBINATION OF EFFICIENCY AND PRECISION

●Designed with a heavy-duty body and box shaped columns, it has good rigidity and high stability

●The three axis adopts linear roller guide rail, which has fast speed and high accuracy.

●Z-axis with band brake, no counterweight design, high-speed movement up and down, no vibration, high accuracy

●Equipped with a head umbrella shaped knife library, it has fast tool replacement and high efficiency.

●The design of the rear debris structure makes slag removal more convenient.

PURSUING HIGH PRODUCTION EFFICIENCY

Pursuing endless production efficiency to achieve faster processing

The Perfect Combiation

Shortened the start and stop time of the spindle, adopted high-speed feed and acceleration, and shortened non machining time. High speed ATC tool exchange mode and adopted a new generation of control system.

|

item |

unit |

HMT600 |

HMT800 |

|

XZ axis travel |

mm |

600/420/330 |

800/420/330 |

|

Distance from spindle end to workbench |

mm |

150-480 |

150-480 |

|

Distance from spindle center to column guide rail surface |

mm |

465 |

465 |

|

Workbench size (length x width) |

mm |

720x400 |

900x400 |

|

T-groove (number size spacing) |

mm |

4-14-80 |

4-14-80 |

|

Allowable load |

kg |

350 |

400 |

|

Spindle taper hole |

No. |

BT30 |

BT30 |

|

Maximum spindle speed |

r/min |

20000 |

20000 |

|

Maximum power of spindle motor |

kw |

5.5 |

5.5 |

|

XYZ axis fast movement speed |

m/min |

60/60/48 |

60/60/48 |

|

Maximum chip speed |

mm/min |

10000 |

10000 |

|

Tool magazine |

|

Clamping arm type tool magazine |

Clamping arm type tool magazine |

|

Number of tools |

T |

16/21 |

16/21 |

|

Positioning accuracy (JIS standard) |

mm |

±0.005/300 |

±0.005/300 |

|

Repetitive positioning accuracy (JIS standard) |

mm |

±0.003 |

±0.003 |

|

Machine weight |

kg |

3800 |

4200 |

|

Overall dimensions (length/width/height) |

mm |

1900/2400/2700 |

2200/2400/2700 |

|

Control system |

|

Mitsubishi M80/Fanuc OI-MF PLUS |

|