Model No.︰HMLM2016

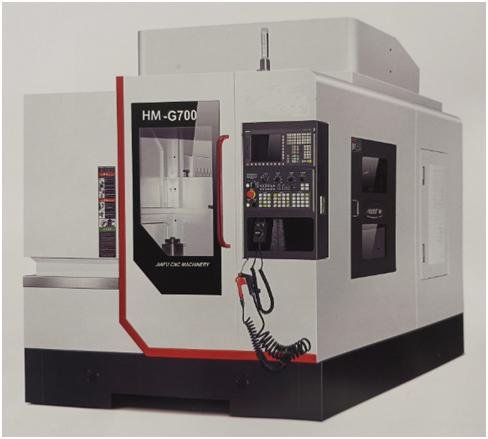

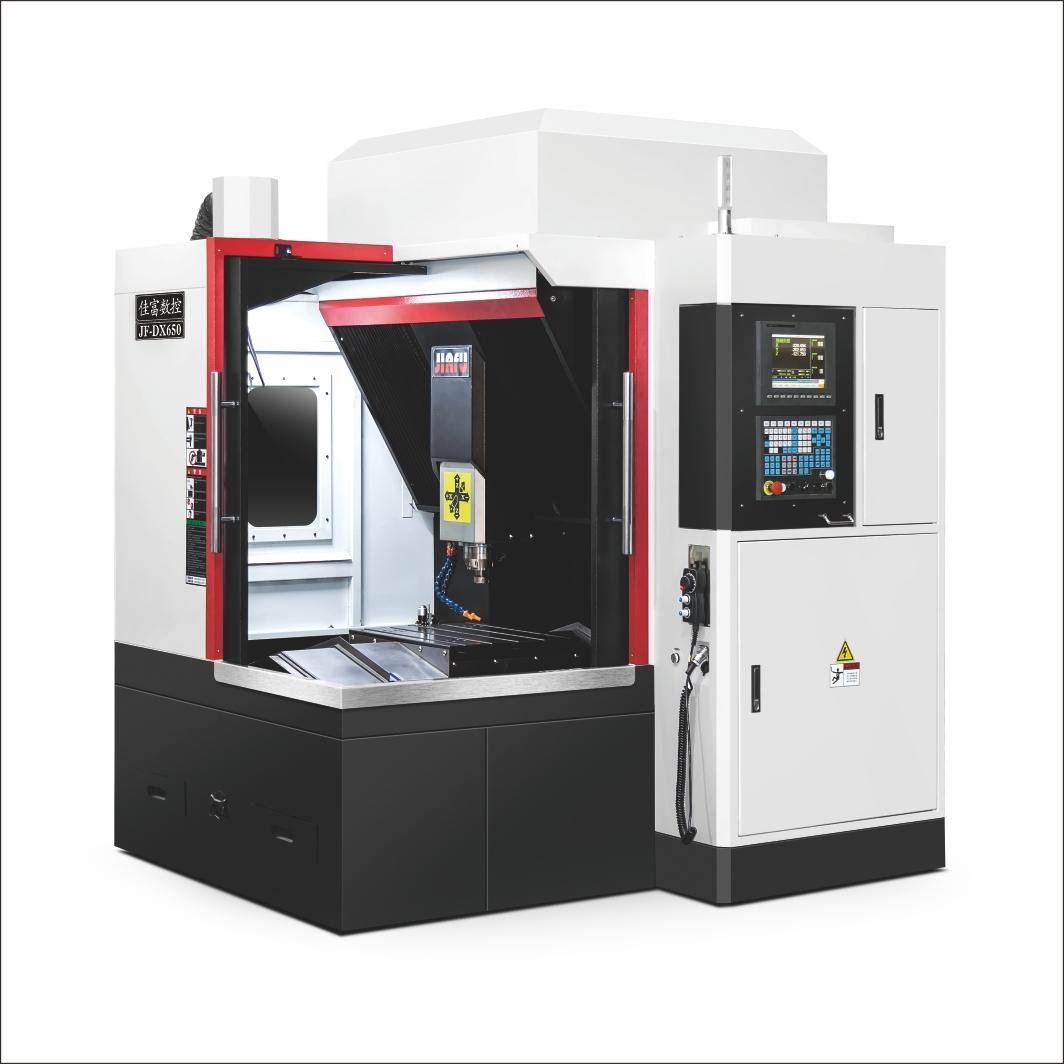

Brand Name︰HMW

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 pc

HEAVYGANTRY MACHINING CENTER SERIES

|

HMLM4025 |

HMLM5025 |

HMLM6025 |

HMLM6032 |

|

HMLM2018 |

HMLM2518 |

HMLM3018 |

HMLM3518 |

|

HMLM3022 |

HMLM4022 |

HMLM5022 |

HMLM3025 |

|

HMLM2016 |

HMLM2516 |

HMLM3016 |

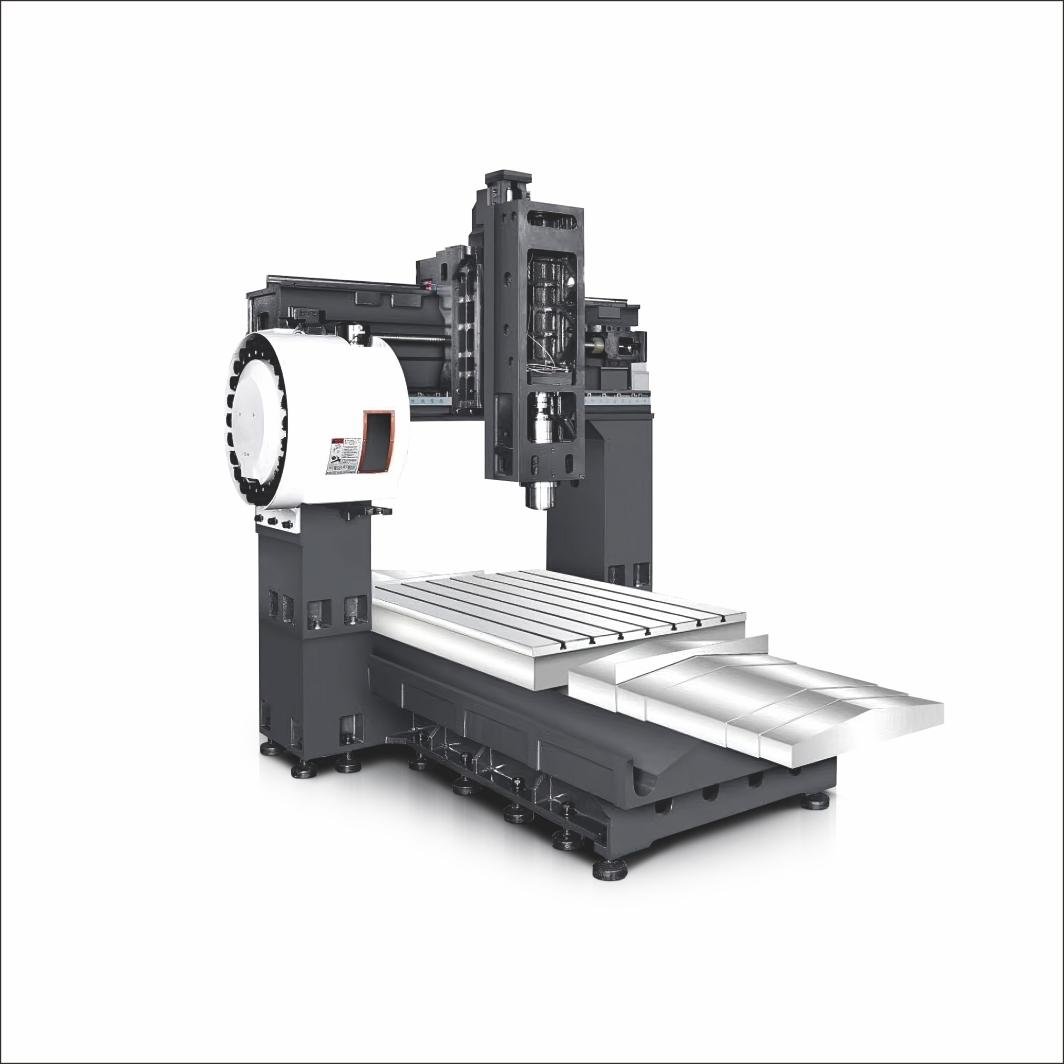

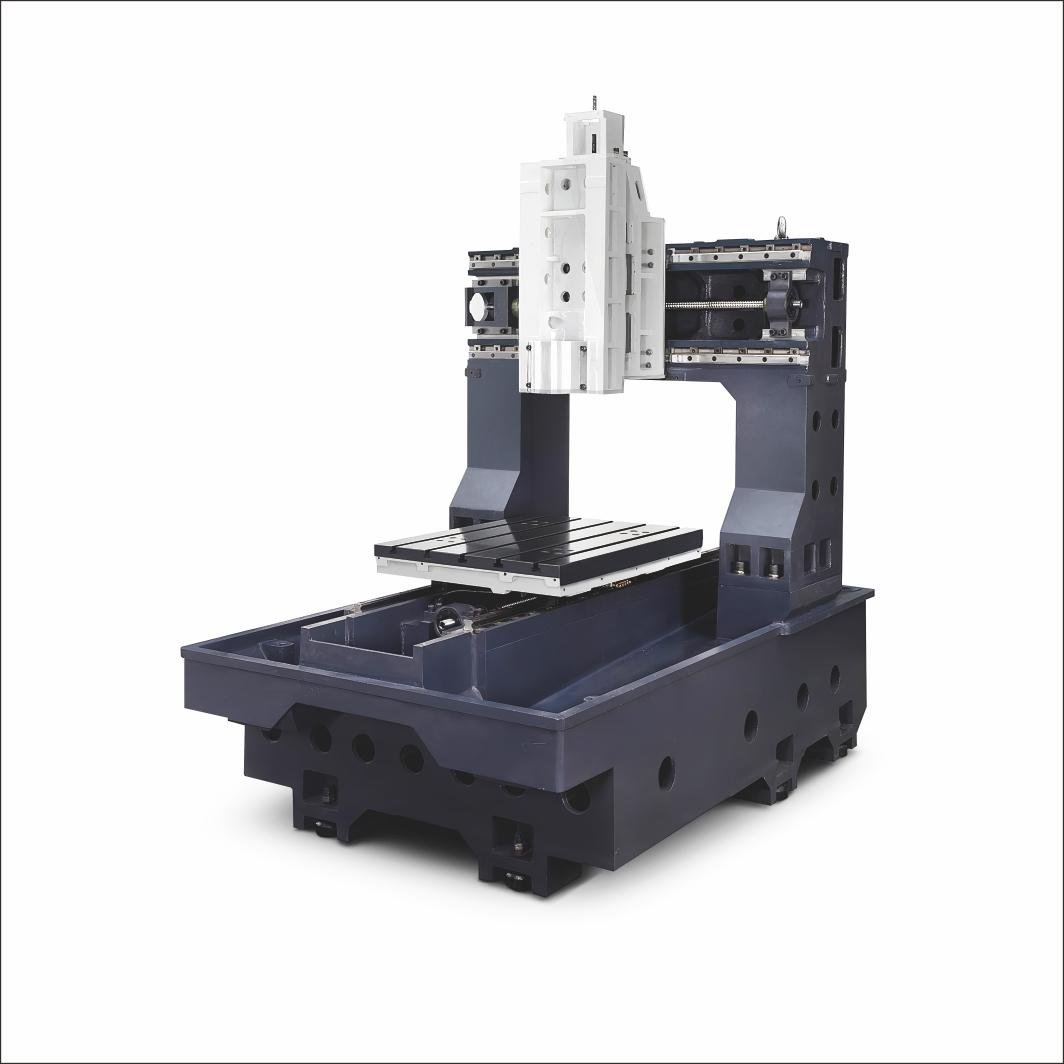

The standard configuration is the XY axis heavy-duty roller track, and the Z axis adopts a rectangular slide rail with high accuracy and strong seismic resistance.

●The Z-axis adopts hydraulic nitrogen balance to ensure stability when moving up and down

●Optional gear reduction box and gear type spindle box for high-strength cutting.

High-precision performance mechanism to achieve the best feed thrust andcutting rigidity of the whole machine

High rigidity structural design, combined with the high-precision indicators of the five sided machining center machine, creates a comprehensive and efficient cutting with a solid structure and excellent geometric accuracy.

LOW NOISE/LOW FRICTION

Heavy duty, high-efficiency, and high-precision gantry, with strict quality, surpassing the competitive standards of peers.

Various Door Width /Various TravelChoice.Can Satisfy Different Machining Requirement

HEAVY GANTRY MACHINING CENTERSERIES

Model technical specifications

|

project |

unit |

Heavy duty gantry machining center |

||

|

HMLM2016 |

HMLM2516 |

HMLM3016 |

||

|

Workbench area (length x width) |

mm |

2000x1300 |

2500x1300 |

3000x1300 |

|

T-groove mesh |

mm |

7 |

7 |

7 |

|

Permissible load |

kg |

4000 |

5000 |

6000 |

|

X/Y/Z axis travel |

mm |

2000/1650/800 |

2500/1650/800 |

3000/1650/800 |

|

Door width |

mm |

1660 |

1660 |

1660 |

|

Distance from spindle end to workbench |

mm |

250-1050 |

250-1050 |

250-1050 |

|

Spindle taper hole |

No. |

BT50 |

BT50 |

BT50 |

|

Maximum spindle speed |

r/min |

6000 |

6000 |

6000 |

|

Maximum power of spindle motor |

kw |

18.5 |

18.5 |

18.5 |

|

feed |

X/Y-axis heavy-duty roller track, Z-axis rectangular plastic coated guide rail |

|||

|

X/Y/Z axis fast movement speed |

m/min |

20/20/16 |

16/16/16 |

16/16/16 |

|

Maximum chip speed |

mm/min |

8000 |

8000 |

8000 |

|

Number of tools |

T |

24 |

24 |

24 |

|

positioning accuracy |

mm |

0.02/1000 |

0.02/1000 |

0.02/1000 |

|

Repetitive positioning accuracy |

mm |

0.015 |

0.015 |

0.015 |

|

Machine weight |

T |

19 |

21 |

23 |

|

Control system |

Mitsubishi M80/Fanuc OI-MF PLUS/Siemens 828D |

|||

|

project |

unit |

Heavy duty gantry machining center |

|

||

|

HMLM2018 |

HMLM2518 |

HMLM3018 |

HMLM3518 |

||

|

Workbench area (length x width) |

mm |

2000x1600 |

2500x1600 |

3000x1600 |

3500x1600 |

|

T-groove mesh |

mm |

9 |

9 |

9 |

9 |

|

Permissible load |

kg |

6000 |

7000 |

8000 |

9000 |

|

X/Y/Z axis travel |

mm |

2000/2000/1000 |

2500/2000/1000 |

3000/2000/1000 |

3500/2000/1000 |

|

Door width |

mm |

1800 |

1800 |

1800 |

1800 |

|

Distance from spindle end to workbench |

mm |

150-1150 |

150-1150 |

150-1150 |

150-1150 |

|

Spindle taper hole |

No. |

BT50 |

BT50 |

BT50 |

BT50 |

|

Maximum spindle speed |

r/min |

6000 |

6000 |

6000 |

6000 |

|

Maximum power of spindle motor |

kw |

18.5 |

18.5 |

18.5 |

18.5 |

|

feed |

X/Y-axis heavy-duty roller track, Z-axis rectangular plastic coated guide rail |

||||

|

X/Y/Z axis fast movement speed |

m/min |

16/16/16 |

16/16/16 |

16/16/16 |

16/16/16 |

|

Maximum chip speed |

mm/min |

8000 |

8000 |

8000 |

8000 |

|

Number of tools |

T |

24 |

24 |

24 |

24 |

|

positioning accuracy |

mm |

0.02/1000 |

0.02/1000 |

0.02/1000 |

0.02/1000 |

|

Repetitive positioning accuracy |

mm |

0.015 |

0.015 |

0.015 |

0.015 |

|

Machine weight |

T |

21 |

23 |

26 |

29 |

|

Control system |

Mitsubishi M80/Fanuc OI-MF PLUS/Siemens 828D |

|

|||

|

project |

unit |

Heavy duty gantry machining center |

|

HMLM3022 HMLM4022 HMLM5022 HMLM3025

Workbench area (length x width) mm 3000x2000 4000x2000 5000x2000 3000x2300

T-groove mesh mm 9 9 9 11

Permissible load kg 10000 12000 14000 10000

X/Y/Z axis travel mm 3000/2200/1000 4000/2200/1000 5000/2200/1000 3000/2700/1000

Door width mm 2300 2300 2300 2700

Distance from spindle end to workbench mm 280-1280 280-1280 280-1280 280-1280

Spindle taper hole No. BT50 BT50 BT50 BT50

Maximum spindle speed r/min 6000 6000 6000 6000

Maximum power of spindle motor kw 22 22 22 22

feed X/Y-axis heavy-duty roller track, Z-axis rectangular plastic coated guide rail

X/Y/Z axis fast movement speed m/min 16/16/16 16/16/16 16/16/16 16/16/16

Maximum chip speed mm/min 8000 8000 8000 8000

Number of tools T 24 24 24 24

positioning accuracy mm 0.02/1000 0.02/1000 0.02/1000 0.02/1000

Repetitive positioning accuracy mm 0.015 0.015 0.015 0.015

Machine weight T 34.8 38.5 45 37

Control system Mitsubishi M80/Fanuc OI-MF PLUS/Siemens 828D

project unit Heavy duty gantry machining center

HMLM4025 HMLM5025 HMLM6025 HMLM6032

Workbench area (length x width) mm 4000x2300 5000x2300 6000x2300 6000x2500

T-groove mesh mm 11 11 11 11

Permissible load kg 12000 15000 18000 25000

X/Y/Z axis travel mm 4000/2700/1000 5000/2700/1000 6000/2700/1000 6000/3200/1250

Door width mm 2700 2700 2700 3200

Distance from spindle end to workbench mm 280-1280 280-1280 280-1280 250-1250

Spindle taper hole No. BT50 BT50 BT50 BT50

Maximum spindle speed r/min 6000 6000 6000 6000

Maximum power of spindle motor kw 22 26 26 26

feed X/Y-axis heavy-duty roller track, Z-axis rectangular plastic coated guide rail

X/Y/Z axis fast movement speed m/min 16/16/16 16/16/16 16/16/16 16/16/16

Maximum chip speed mm/min 8000 8000 8000 8000

Number of tools T 24 24 24 24

positioning accuracy mm 0.02/1000 0.02/1000 0.02/1000 0.02/1000

Repetitive positioning accuracy mm 0.015 0.015 0.015 0.015

Machine weight T 43 47 55 86

Control system Mitsubishi M80/Fanuc OI-MF PLUS/Siemens 828D