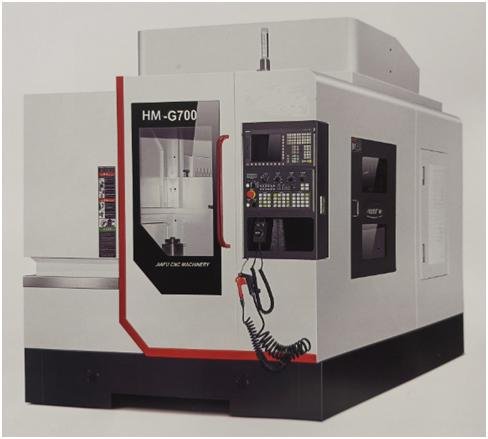

Model No.︰HM G700

Brand Name︰HMW

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 pc

HM G700

GANTRY HIGH-SPEED MACHINING CENTER

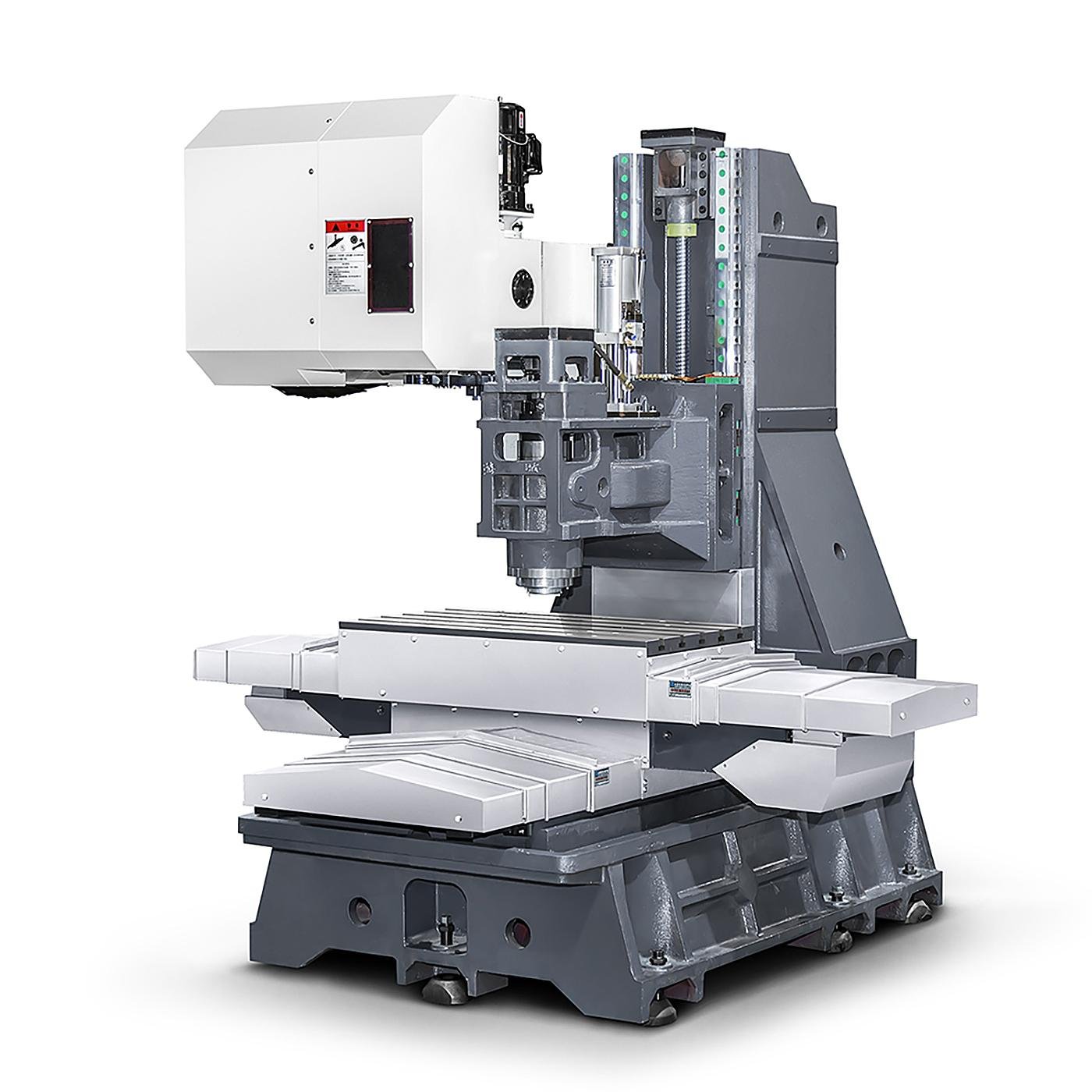

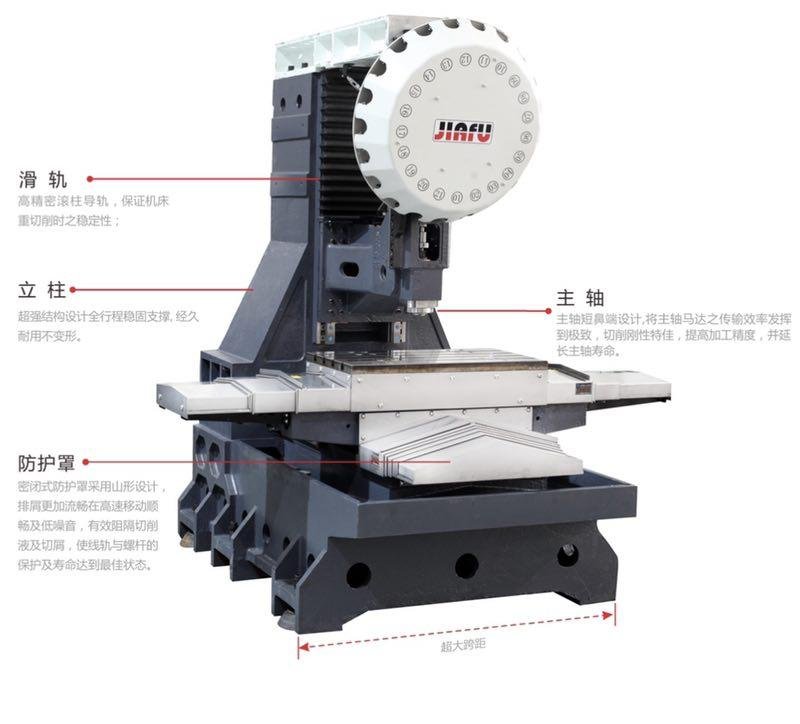

●This machine adopts a high rigidity fixed beam gantry structure and is equipped with an HSKA6320000rpm electric spindle, which perfectly combines high-speed and high rigidity. It is particularly suitable for high-speed and high-precision processing of small and medium-sized molds and related industrial parts.

●Gantry structure, overweight body design, and good machine tool stability.

●The integrated design of columns and crossbeams reduces the deformation of the machine tool, making it more stable.

●The three axis adopts precise linear guide rails, with fast displacement speed and high accuracy.

●Using a high-speed spindle, with high rotational speed and good accuracy.

●Fully enclosed external design reduces environmental pollution caused by oil mist generated by high-speed machining.

SMALL AND MEDIUM-SIZED MOLD PROCESSING BEST WEAPON!

GANTRY STRUCTURE, COMBINING RIGIDITY AND SPEED, CAN ACHIEVE HIGH PRECISION AND HIGH SMOOTHNESS

|

item |

unit |

HMG700 |

|

X/Y/Z axis travel |

mm |

700/600/450 |

|

Door width |

mm |

900 |

|

Distance from spindle end to workbench |

mm |

100-550 |

|

Workbench area (length x width) |

mm |

800x600 |

|

Permissible load |

kg |

1000 |

|

Spindle specifications |

|

HSKA63/Φ150electric spindle |

|

Maximum spindle speed |

r/min |

20000 |

|

Spindle motor power |

kw |

20 |

|

X/Y/Z axis fast movement speed |

m/min |

30/30/30 |

|

Maximum chip speed |

mm/min |

10000 |

|

Number of tools |

T |

16 |

|

Positioning accuracy (JIS standard) |

mm |

±0.005/300 |

|

Repetitive positioning accuracy |

mm |

±0.003 |

|

Machine weight |

kg |

6800 |

|

Machine tool dimensions (length/width/height) |

mm |

2400/2600/2600 |

|

Control system |

|

Siemens 828D/Fanuc OI-MF PLUS |