Model No.︰HZ1003E

Brand Name︰HarmonyWOLRD/OEM/ODM

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 pc

Computer-based servo universal material testing machine is a new type of material testing machine that combines electronic technology and mechanical transmission. It has a wide and accurate loading speed and force measuring range, high accuracy and sensitivity for the measurement and control of load and displacement, and can also carry out automatic control tests of constant speed loading and displacement. It is easy to operate, especially suitable for production line

The imported photoelectric encoder is used for displacement measurement. The controller adopts embedded single chip microcomputer structure and built-in powerful measurement and control software, which integrates measurement, control, calculation and storage functions. It has the function of automatic calculation of stress, elongation (extensometer is required), tensile strength and elastic modulus, and automatic statistics of results; Automatically record the force value or elongation at the maximum point, breaking point and designated point; The computer is used to dynamically display the test process and test curve, and to process the data. After the test, the curve can be amplified through the graphics processing module to analyze and edit the data, and the report can be printed. The product performance reaches the international advanced level.

Meet the standard

Meet the standard GB/T 16491-2008 electronic universal testing machine, and meet many domestic and international test standards such as ASTM D412, ASTM D638, GB/T 1040, GB/T 8808, GB/T 13022, GB/T 2790, GB/T 2791, GB/T 2792, GB/T 16825, GB/T 17200, GB/T 3923.1, GB/T 2611, GB/T 6344, GB/T 20310, GB/T 3690, GB/T 4944, GB/T 3686, GB/T 6344, GB/T 10654, B/T 7124 and ASTM D1876.

major function

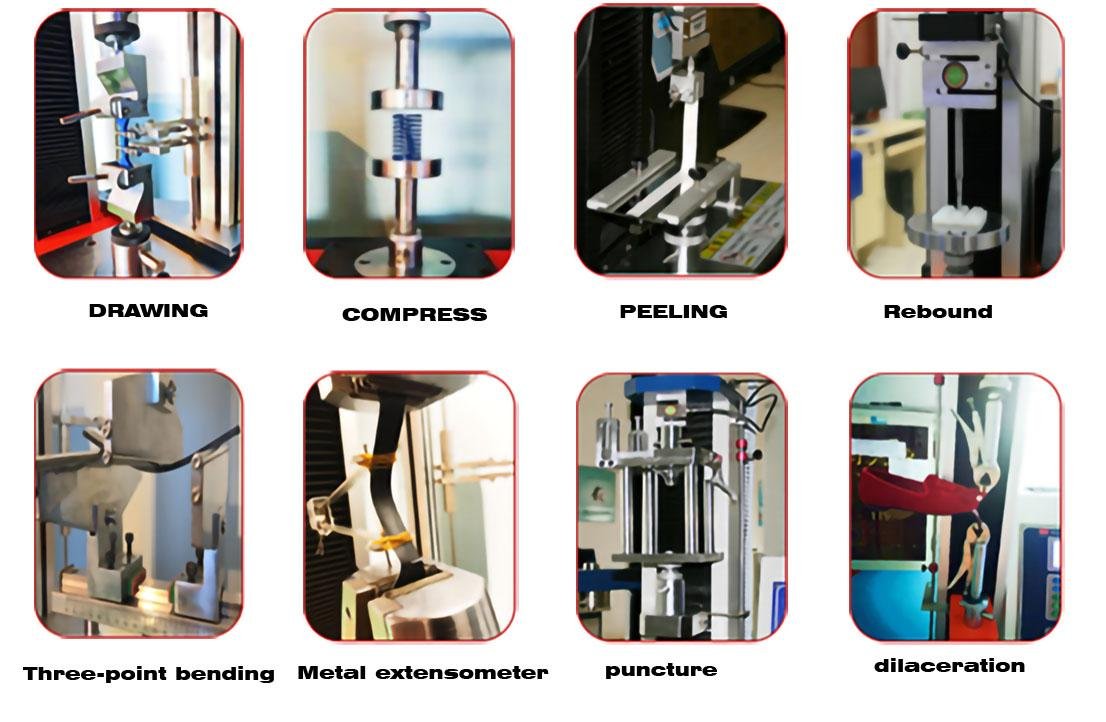

It is mainly applicable to the test of metal and non-metallic materials, such as rubber, plastic, wire and cable, optical fiber and cable, safety belt, leather belt composite, plastic profile, waterproof coiled material, steel pipe, copper, profile, spring steel, bearing steel, stainless steel (and other high hardness steel), casting, steel plate, steel strip, non-ferrous metal wire have tensile, compression, bending, shearing, peeling, tearing Multiple tests such as two-point extension (fixture spacing calibration).